Deep groove ball bearings

Deep groove ball bearings are the most widely used bearing type and are particularly versatile. They have low friction and are optimized for low noise and low vibration which enables high rotational speeds. They accommodate radial and axial loads in both directions, are easy to mount, and require less maintenance than other bearing types.

The SKF bearing catalogue lists a large range of designs, variants and sizes of deep groove ball bearings. Beyond our catalogue offering, the SKF Explorer deep groove ball bearings are customizable to offer advantages for applications with specific performance needs.

- Single row deep groove ball bearings

- Stainless steel deep groove ball bearings

- Single row deep groove ball bearings with filling slots

- Double row deep groove ball bearings

- Bearing data

- Loads

- Temperature limits

- Permissible speed

- Designation system

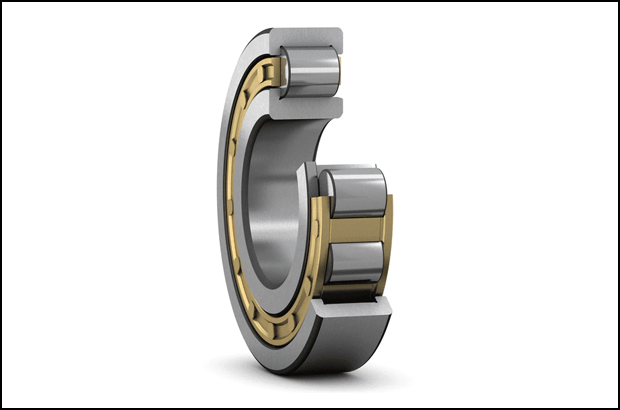

Cylindrical roller bearings

SKF Cylindrical roller bearings are available in a wide range of designs, series, variants and sizes. The main design differences are the number of roller rows and the inner/outer ring flanges as well as cage designs and materials.

The bearings can meet the challenges of applications faced with heavy radial loads and high speeds. Accommodating axial displacement (except for bearings with flanges on both the inner and outer rings), they offer high stiffness, low friction and long service life.

Cylindrical roller bearings are also available in sealed or split designs. In sealed bearings, the rollers are protected from contaminants, water and dust, while providing lubricant retention and contaminant exclusion. This provides lower friction and longer service life. Split bearings are intended primarily for bearing arrangements which are difficult to access, such as crank shafts, where they simplify maintenance and replacements.

Thrust ball bearings

SKF thrust ball bearings are manufactured as single direction or double direction thrust ball bearings. They are designed to accommodate axial loads only and must not be subjected to any radial load.

In addition to the bearings presented in this section, SKF supplies thrust ball bearings for special application requirements. This assortment includes bearings with Solid Oil and NoWear coated bearings.

- Designs and variants

- Bearing data

- Loads

- Temperature limits

- Permissible speed

- Mounting

- Designation system

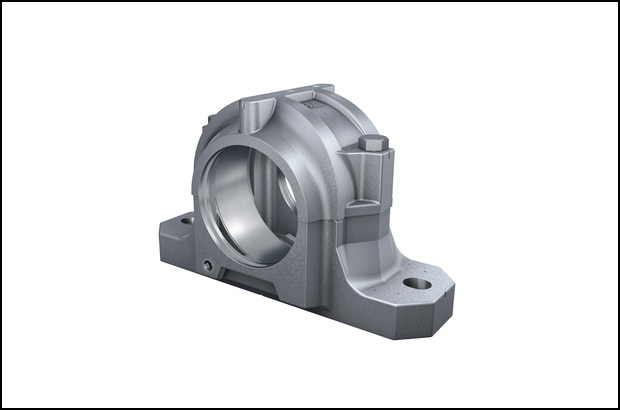

Plummer block housing

Split plummer block housing for various bearing designs. The SNV series will be replaced by the new SES series in 2022.

Angular Contact Ball Bearings

In angular contact ball bearings, the forces are transmitted from one raceway to the other at a specific contact angle (oblique to the radial plane). The bearings are therefore suitable for radial and axial loads acting simultaneously.

As the nominal contact angle increases, so does the axial load carrying capacity. As a result, angular contact ball bearings are more suitable than deep groove ball bearings for supporting higher axial forces.

The bearings are available in a single row design as single bearings or as a pair of universal bearings as well as in a double row design.

Single row angular contact ball bearings are particularly suitable where:

- bearing arrangements must support combined loads

- moderate to high axial loads are present on one side

- rigid axial guidance is required

- the bearing arrangement must be axially clearance-free or preloaded

- high speeds are required under higher radial and axial loads.

Double row angular contact ball bearings are particularly suitable where:

- the design envelope is not sufficient under high loads for a pair of single row angular contact ball bearings

- high radial and axial loads are acting simultaneously

- tilting moments must also be supported

- a relatively rigid bearing arrangement is required.

Axial cylindrical roller bearings have a high axial load carrying capacity, are extremely rigid and can support axial forces in one direction. Axial cylindrical roller bearings have a greater load carrying capacity than axial needle roller bearings with the same bearing diameter.

Axial cylindrical roller bearings are particularly suitable where:

- high axial and shock locks occur in one direction and no radial loads are present

- the load carrying capacity of comparable axial deep groove ball bearings is no longer sufficient

- the axial space available is only very small

- the bearing parts can or must be mounted separately.

Axial cylindrical roller bearings are available as:

- complete single and double row bearings

- individual bearing parts for combination, comprising axial cylindrical roller and cage assembly, housing locating washer and shaft locating washer; bearing washers can be used as an alternative to the housing and shaft locating washer).

- The use of complete axial cylindrical roller bearings is then advisable if, for example, high speeds occur and the bearing washers must therefore be centred precisely.

- If the available axial space is small, it may be helpful to integrate the axial cylindrical roller and cage assembly directly in the adjacent construction. The running surfaces for the rolling elements must therefore be produced as rolling bearing raceways.

Tapered Roller Bearings

Tapered roller bearings comprise an outer and inner ring with tapered raceways as well as tapered rollers in a window cage. These are single row individual bearings, usually of open design, which for technical reasons are always adjusted against a second tapered roller bearing in a mirror image arrangement. Open bearings are not self-retaining. As a result, the inner ring with the rollers and the cage can be mounted separately from the outer ring.

Tapered roller bearings can support high radial and axial loads in equal measure. Depending on the arrangement, they are suitable when precise axial guidance of the shaft is required (locating bearing function), or when the bearing arrangement must have very high axial rigidity and be operated clearance-free or under preload.

Tapered roller bearings are available as:

- single row tapered roller bearings of standard design

- matched tapered roller bearings (fitted in pairs in X, O or tandem arrangement, open design)

- integral tapered roller bearings (fitted in pairs, sealed on one side, not separable).

Axial-angular Contact Roller Bearings

Angular contact roller bearings AXS comprise thin, formed bearing rings, between which injection-moulded plastic cages with cylindrical rollers are arranged. In contrast to comparable axial rolling bearings, series AXS has a particularly small cross-section, whilst the load carrying capacity and tilting rigidity are very high in relation to the loaded installation space. The ready-to-fit machine elements are not self-retaining and are therefore very easy to assemble as the individual parts can be installed separately.

Angular contact roller bearings SGL are preferably used if high accuracy and rigidity is required in addition to a high load carrying capacity. The particularly high precision is achieved by means of exact, machined, hardened and ground bearing rings with a triangular profile. A roller and cage assembly from wear-resistant plastic is arranged between the bearing rings. The use of quadratic rolling elements (diameter equals length) significantly improves the kinematic conditions in the bearing. The bearing runs particularly uniformly with low friction and is suitable for high speeds.

Angular contact roller bearings SGL have long proven successful in low-clearance planetary gearboxes for precision drives. Possible areas of application include handling systems, packaging machinery, food processing and robotics.

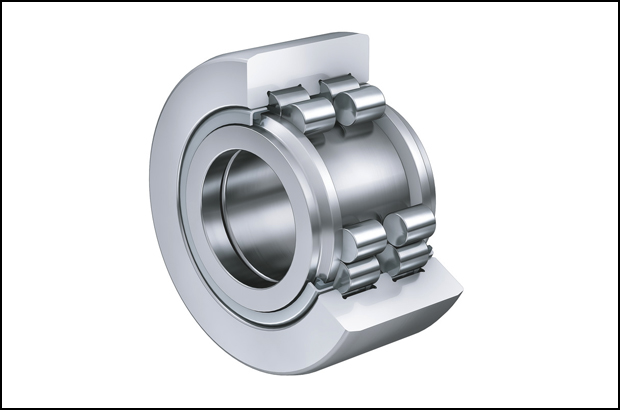

Yoke type track rollers

Yoke type roller bearing track rollers are ready-to-fit needle or cylindrical roller bearings of single or double row design.

They have particularly thick-walled outer rings with a crowned outside surface (also available with a cylindrical outside surface on request), can support high radial loads and tolerate axial loads which are due to small misalignments, skewed running or temporary contact running impacts.

Yoke type roller bearing track rollers are mounted on a shaft or stud. They are not mounted in a housing bore but supported on a flat raceway (mating track).

Yoke type roller bearing track rollers are available with or without an inner ring. They are produced with or without axial guidance of the outer ring.

Yoke type roller bearing track rollers are open or sealed on both sides.

Rod Ends

Rod ends are spherical plain bearing units. They comprise a housing and integral shank, into which a spherical plain bearing is integrated, and have an external or internal thread. Rod ends are used as connecting levers and connecting rods and as connecting elements between cylinders and their adjacent parts in hydraulic and pneumatic cylinders.

The rod ends can support radial forces in a tensile or compressive direction. They are suitable for slow movements with small to moderate swivel angles, for unilateral load and under certain conditions for alternating loads.

Rod ends are available maintenance-free as a standard design and as corrosion-resistant rod ends made from high-grade steel as well as with CETOP mounting dimensions.