Pressure Gauge

Bourdon tube pressure gauge, stainless steel

Application

- For gaseous and liquid aggressive media that are not highly viscous or crystallising, also in aggressive environments

- Chemical and petrochemical industries, oil and gas industry, power engineering and also water and wastewater technology

- Machine building and general plant construction

Special Features

- Excellent load-cycle stability and shock resistance

- With case filling (model 233.50) for applications with high dynamic pressure loads and vibrations

- Completely from stainless steel

- Scale ranges from 0 … 0.6 to 0 … 1,600 bar [0 ... 10 to 0 ... 20,000 psi]

Digital Pressure Gauges (Calibration)

Precision digital pressure gauge

Application

- Oil and gas industry

- Maintenance and service facilities

- Calibration service companies and service industry

- Simple calibrations directly on site

Special Features

- Measuring ranges up to 0 ... 1,000 bar (0 ... 15,000 psi), vacuum and absolute pressure ranges also available

- Accuracy: up to 0.05 % (incl. calibration certificate)

- Intrinsically safe version

- Logger function with up to 50 measured values per second

- Communication with WIKA-CAL software over WIKA-Wireless

Thread Gauge

- Gauge dimensions for Acme threads are as per ASME B1.5 and Stub Acme as per ANSI/ASME B1.8

- Most commonly used class is 2G. If less backlash is desired in acme threads, 3G & 4G class are used

- The height of Acme threads is 0.5p, whereas the height of Stub Acme threads is 0.3p

Thread Gauge: Unified

The GO gauge when screwed by hand without using excessive force, should enter and pass the whole length of the workpiece thread. The NOT GO gauge when screwed by hand without being forced, should not enter the component by more than three complete turns.

Setting Rings for Air Plug Gauge

- Used for setting of pneumatic length measuring instruments

- Made from oil hardening non shrinking gauge steel, hardened and tempered to 60-62 HRC

- Subzero treated at -800C for long term dimensional stability

- Actual dimensions duly etched

- Calibrated at 200C under Standards Room conditions against National/International traceable standards

- Certificate of calibration is provided along with each master traceable to National/International standards. Certificate under NABL (as per ISO 17025) as per request

- Manufactured as per DIN2250-1 Type B

Go Spline Ring Gauge and Taper Master Plug

Taper tooth master plugs with fit and wear lines beautifully exemplify Spline Gauges’ exacting specialty engineering. These are used to monitor the wear of ring gauges during component manufacture. The ring gauge is ground to fit the master plug for original and replacement ring gauges.

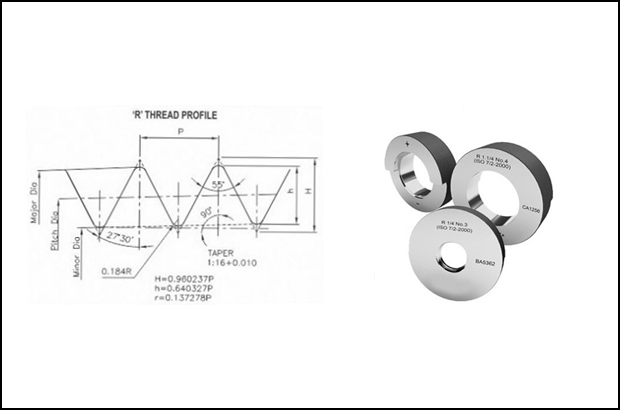

M / KEG Taper Thread Gauges

M KEG Metric Taper Threads are used for oil & grease Nipples where self sealing connections can not be obtained by parallel threads with sealing washers.

Specification

DIN Standard: Basic Dimensions : DIN 158 Part 1 : 1997 & Gauging Practice : DIN 158 Part 2 : 1997

Manufacturing Range

Parallel Limit Ring Gauges AND Taper Threaded Check Plug Gauge to check parallel ring for diameters from Mc5 to Mc60. Pitches covered are from 0.8 , 1, 1.25, 1.5 & 2 mm. We also manufacture Taper Ring Gauges as per old DIN 158 : 1986 specification.

Plain Plug Gauges

12mm [H7] Go/No-Go Plain Plug Gauges (Insize 4124)

- 1 Year Extended Warranty.

- Free Technical Support From Our Engineers.

- Gauge Size: 12mm

- Tolerance Class: H7

- Go Tolerance: +0.001mm/+0.004mm

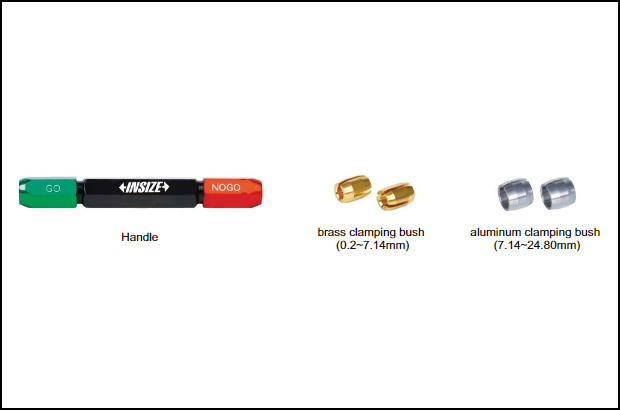

Pin Gage Handels

- Wrench is needed to install pins

- Clamping bushes (0.2 ~ 7.14 mm) are made of brass.

- Clamping bushes (7.14 ~ 24.80 mm) are made of Aluminum.