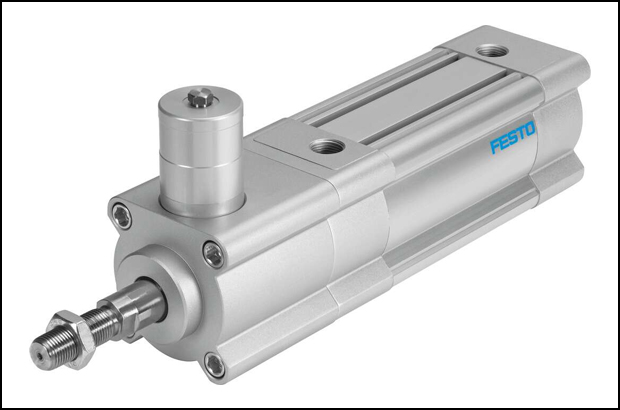

Compact air cylinder, double-acting ADN

ISO cylinder to ISO 21287 for fixed or self-adjusting cushioning with high variance

- ISO 21287

- Up to 50% less installation space than comparable ISO cylinders to ISO 15552

- Piston rod with internal or external thread

- Wide range of variants for customized applications

- Magnetic piston for position sensing

- Variants recommended for production facilities for the manufacture of lithium-ion batteries

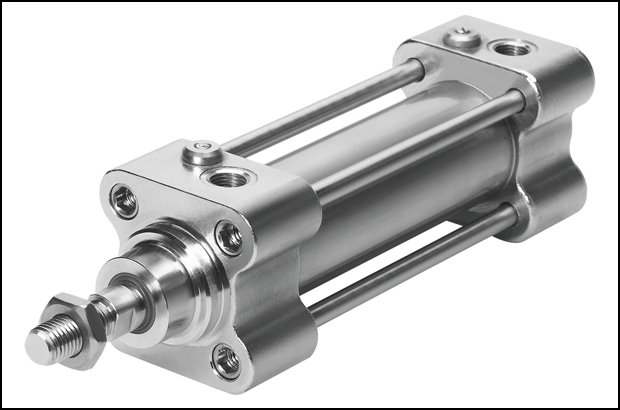

ISO cylinder CRDNG

Corrosion resistant against aggressive ambient conditions. Variant models: through piston rod; heat-resistant version

- ISO 15552 (ISO 6431, VDMA 24562)

- Corrosion resistant against aggressive ambient conditions

- Easy-to-clean design

- Variants: through piston rod, heat-resistant design

- Nose mounting, mounting via accessories

- Magnetic piston for position sensing

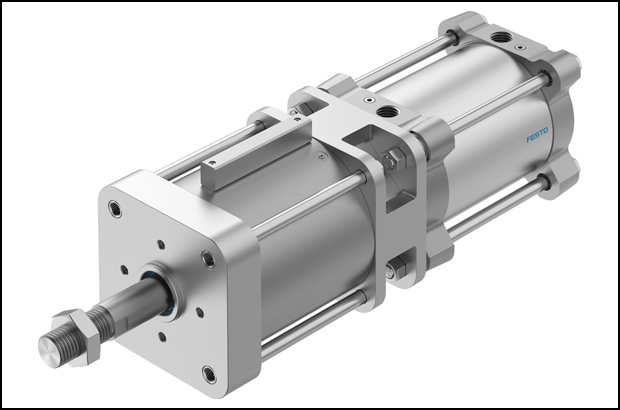

ISO standard profile tube air cylinder with clamping cartridge DSBC-C

ISO profile cylinder to ISO 15552 with clamping fixture for the piston rod. A wide range of mounting options. Without additional measures for compliance with statutory minimum requirements, the product is not suitable as a safety-relevant component in control systems.

- Piston rod can be held in any position

- Piston rod can be held in position for long periods even with alternating loads, fluctuating operating pressure, or leaks in the system

- Mounting hole pattern to ISO 15552

- Piston rod with internal or external thread

- Magnetic piston for position sensing

Cylinder with holding brake

- Stroke : 10 mm ... 2000 mm

- Piston diameter : 160 mm

- Piston rod thread : M36x2

- Based on norm : ISO 15552 (previously also VDMA 24562, ISO 6431, NF E49 003.1, UNI 10290)

- Cushioning : Pneumatic cushioning, adjustable at both ends

- Mounting position : Any

- Clamping type with active direction : Both sides, Clamped by spring, released by compressed air

- Piston rod end : External thread

- Structural design : Piston, Piston rod, Profile barrel

- Position sensing : For proximity sensor

- Symbol : 995696

- Variants : Piston rod at one end

- Safety function : Holding and stopping a movement

- Performance Level (PL) : Stopping, holding, blocking of movement/Category 1, Performance Level c

- Operating pressure : 0.6 bar ... 8 bar

- Max. permissible test pressure : 8 bar

- Min. release pressure : 3.8 bar

- Mode of operation : Double-acting

- Certification : German Technical Control Board (TÜV)

- CE marking (see declaration of conformity) : as per EU machinery directive

- Explosion prevention and protection : Zone 1 (ATEX), Zone 2 (ATEX), Zone 21 (ATEX), Zone 22 (ATEX)

- Certificate issuing authority : TÜV CA 697

- ATEX category gas : II 2G

- ATEX category for dust : II 2D

- Type of ignition protection for gas : Ex h IIC T4 Gb

- Type of (ignition) protection for dust : Ex h IIIC T120°C Db

- Explosive ambient temperature : -20°C <= Ta <= +60°C

- Operating medium : Compressed air as per ISO 8573-1:2010 [7:4:4]

- Corrosion resistance class (CRC) : 1 - Low corrosion stress

- Ambient temperature : -20 °C ... 80 °C

- Cushioning length : 48 mm

- Static holding force : 17000 N

- Theoretical force at 6 bar, retracting : 11310 N

- Theoretical force at 6 bar, advancing : 12064 N

- Moving mass at 0 mm stroke : 7085 g

- Additional weight per 10 mm stroke : 208 g

- Basic weight with 0 mm stroke : 49660 g

- Additional moving mass per 10 mm stroke : 97 g

- Type of mounting : With internal thread, With accessories

- Clamping unit release connection : G3/8

- Pneumatic connection : G3/4

- Note on materials : RoHS-compliant

- Cover material : Die-cast aluminum, Wrought aluminum alloy

- Seals material : NBR, TPE-U(PU)

- Housing material : Steel

- Piston rod material : Steel, hard-chrome-plated

- Material of cylinder barrel : Wrought aluminum alloy, smooth-anodized

Regulators for Ultra High Purity (UHP) AP/SL/AP/AZ

- For UHP gas delivery in semiconductor and other clean industries.

- Body material: 316L SS secondary remelt or 316L SS

- Electropolished wetted parts

- Metal seal to atmosphere