Surface Conditioning Low Stretch Belt

- Durable cloth / polyester scrim backing is ideal for low-stretch applications

- Removes grindlines, mills and other marks conveniently

- Superior backing and non-woven open web material offers detailed work over contours and edges

- Springy non-woven nylon fibers finish while maintaining the geometry of the piece

- Superior build ensures durability

Standard Abrasives Zirconia GP Flap Disc

- Flaps offer single-step grinding and blending and may replace grinding wheels and fiber discs

- Flap construction leaves a smooth finish and resists gouging

- Zirconia GP material is ideal for low pressure applications

- Overlapping layers extend durability for prolonged use in industrial operations

- Cotton backing resists tearing or fraying

- Phenolic resin plate provides cushion effect for optimal blending and dampens vibration, reducing operator fatigue and tool wear

Sanding Screen

- Rinse and re-use

- Use both sides of screen for long life

- Reduces loading

- Use wet or dry

3M™ Cubitron™ II Depressed Center Grinding Wheel

3M™ Cubitron™ II Depressed Center Grinding Wheel is constructed of 3M precision-shaped ceramic grain to bring you an exceptionally fast-cutting and long-lasting rigid bonded wheel for heavy weld removal and other heavy-duty grinding applications. Our grinding wheel works well on almost all materials and is specially formulated for use on stainless steel, mild steel, and aerospace alloys.

For a grinding wheel which outperforms its competitors in cut and longevity, use 3M™ Cubitron™ II Depressed Centre Grinding Wheel. Our grinding wheels have 3M Precision Shaped Grain which provides a cool extra sharp cut long after other wheels are consumed. The Precision Shaped Grain forms into triangular points that slice through metal rather than gouging or ploughing like traditional abrasives. These points continuously self-sharpen as they fracture, generating an extremely fast cut. This lessens heat build-up due to friction, reducing heat-related stress cracks and discolouration. The depressed centre allows grinding at any angle without damaging the surrounding surface. Our grinding wheels are rigid resin bonded, are 7mm thick and are useful for removing welds from internal angles. They must be used with a wheel guard which fits the size of the wheel. The grinding wheels must have a maximum operating speed greater than or equal to the maximum speed of the grinder used.

- 3M™ Cubitron™ II grain cuts extra fast and cool and is ideal for weld removal in industrial operations

- 3M-engineered triangular shaped grain wears evenly, runs cool, and optimizes mineral breakdown, providing extra long life for wheel and tool

- Specially formulated for use on almost all materials including stainless steel, mild steel, and aerospace alloys

- Quick change attachment enables easy change-outs by hand without tools

- Wheel must have a maximum operating speed greater than or equal to the maximum speed of the power tool used and must be used with a properly sized wheel guard

3M™ Flap Wheel 747D

Our 3M™ Flap Wheel 747D was designed for light grinding, blending, deburring, and polishing on a variety of metals. Ceramic abrasive covered flaps conform to the work piece and provide a smooth clean finish.

Mixed Ceramic Abrasive

Each flap on the 3M™ Flap Wheel 747D is covered with a ceramic abrasive mix, which was designed using a proprietary process to enhance toughness and hardness of the grain. For increased performance, this mix features aluminum oxide blended with 3M ceramic grain to create a harder, longer lasting abrasive. Perfect for light to moderate stock removal, ceramic abrasives are engineered to cut fast and handle intense heat and stress applications. Ceramic/aluminum oxide blend surpasses aluminum oxide abrasives in cut rate and durability and makes it an excellent choice for moderate stock removal and surface preparation.

High Quality Construction

The abrasive mix is attached to a flexible cotton backing using a resin bond. This resin bonding material is specially designed to resist thermal and chemical deterioration, which can occur during high speed sanding. This bond is very hard which allows for faster cuts and a higher cut rate. This wheel also includes a grinding aid for cooler running on stainless steel. Each flap uses an X weight cotton backing, which provides a tough, but flexible surface that bends to fit any work piece. As the wheel is used, the self cutting flaps wear away to expose sharp, new abrasive material, assuring that surfaces are sanded consistently throughout the life of the wheel.

Flap Wheel Advantages

Coated abrasive flap wheels are the ideal choice for light grinding, blending, graining and scale removal on a variety of metals. The abrasive flaps offer a long lasting supply of fresh abrasives and a load resistant design. 3M™ flap wheels are available in both flange mounted and spindle mounted constructions with general purpose aluminum oxide or high performing 3M ceramic aluminum oxide blend abrasive grain.

- Ceramic aluminum oxide blend offers excellent cut rate and life for better performance

- X-weight cotton backing withstands aggressive sanding and grinding

- Resin bonding resists thermal and chemical deterioration for extended wheel life

- Abrasive flap design provides a soft and smooth cut on rounded or irregular surfaces

- Includes a grind-aid to provide cooler running on stainless-steel and other metals

Standard Abrasives™ Aluminum Oxide Flexible Flap Wheel

Designed to keep dust off the workpiece, the Standard Abrasives™ Aluminum Oxide Flexible Flap Wheel produces a straight line finish on inside diameters or contours. Use this wheel to deburr edges, remove flash, and smooth parting lines. A wide range of diameters with different attachment styles enables consistent coverage on many different workpieces.

Improved Finish and Dust Control on Radiused and Contoured Parts

A flap wheel comes in handy when you're faced with the challenge of cleaning up burrs and parting lines on radiused or specially shaped parts where coated discs are not conformable enough or do not have the necessary reach. We designed our Standard Abrasives™ Aluminum Oxide Flexible Flap Wheel with radiused flaps that, compared to our standard Flap Wheel, provide greater flexibility for improved finishing. The radiused flaps also brush dust away from the contact area for a cleaner work environment.

We offer our Flexible Flap Wheel in smaller diameters for attachment to hand-held tools, and larger diameters for off-hand applications. Some power tools may require an additional reducer bushing or adapter for attaching the wheel.

A broad selection of grades is available to deburr edges, remove flash and parting lines, blend machine marks, apply a linear scratch pattern, or provide light blending, cleaning, or polishing.

Small Wheels Access Inner Radiuses and Maintain Maximum Control

Our wheels with smaller diameters provide access to smaller and harder-to-access inner radiuses or contours on irregular parts. They are especially useful for deburring or finishing the insides of tubing. For these smaller areas, flexible flap wheels provide a softer touch than rolls or bands, which are suitable when more aggressive material removal is required, and produce a softer finish than standard flap wheels.Our smaller wheels are 1-3˝ in diameter have a 1/4˝ steel mandrel or a 1/4˝-20 threaded steel shank to enable fast yet secure product changeouts. In each case the steel attachment runs the full width of the wheel center, reducing chatter in the rotation. As a result, you get

- Flexible flaps provide excellent finish on flat and contoured surfaces

- Coated abrasive flaps clean and deburr inner diameters and contours

- Produces a linear scratch pattern

- Steel mandrel reduces chatter

- Aluminum oxide cuts quickly and suits ferrous and non-ferrous materials

- Available in a broad range of sizes and grades to suit almost any part

3M™ Utility Cloth Roll 314D

3M™ Utility Cloth Roll 314D provides light-weight cloth sanding strips used for hand sanding in many different applications. Constructed with aluminum oxide abrasive, our utility rolls come in a range of grades for common applications such as deburring, blending and repairing metal finishes, rust or other contaminant removal, and surface preparation for paints and coatings.

The desired length of the strip can be torn from the roll for a specific application. Most grades have a light, J-weight cloth backing that provides the flexibility needed to conform to circular edges, angles, or other contours. Rolls in grades P50 or P60 have a slightly stiffer X-weight backing suitable for more coarse sanding applications. Cloth remains durable even when bent or rolled, without tearing or shelling, but strips can be torn by hand when a smaller piece is needed, without compromising the sanding surface.

Aluminium oxide is a popular choice among industrial professionals because of its fast cut-rate and long life. This mineral makes a tough, durable abrasive that self-fractures to expose fresh cutting edges, whereas traditional natural abrasives dull more quickly. Aluminium oxide is suitable for a wide variety of materials in both woodworking and metalworking, including ferrous alloys. Aluminium oxide abrasive can be used on ferrous and non-ferrous metals, wood, and plastic.

- Versatile aluminium oxide abrasive roll can be used on metal, wood, and plastic

- Cloth backing is both flexible and durable to withstand heavy use

- Strips can be torn to size and wound around circular pieces, twisted to fit cylinders, or folded to reach into corners

- Handy packaging provides portability

Standard Abrasives™ MD Mini-Brush

Our Standard Abrasives™ MD Mini-Brush features medium density (MD) Buff and Blend material for efficient restoration of original, high-quality finishes on fabricated steel parts. While welds or other imperfections might detract from a fine finish, the original luster can still be salvaged – even revitalized and renewed – with the help of this abrasive brush.

Restoring Original Finishes

Conventional methods for blending weld traces and other imperfections can be time consuming and unpredictable. The Standard Abrasives™ MD Mini Brush restores the original appearance of metal parts quickly and easily. Users begin by welding and setting the grain as normal. Then, the Standard Abrasives™ MD Mini Brush follows to deliver stainless finishes.

The brush is constructed by attaching thin flaps of abrasive material mounted to a fiberglass core. Its design utilizes the ˝face˝ of the material rather than the ˝edge.˝ resulting in fine finishes without leaving the traces of lines associated with ganged arbor hole discs. The flaps are buoyant and responsive, so, rotating on the workpiece they splay out subtly and cover more surface area to eliminate gaps. The brush easily attaches to a die grinder or rotary tool and can be brought to the workpiece if necessary.

Medium Density Material Produces Fine Finishes

Our MD Mini Brush utilizes our Standard Abrasives™ Buff and Blend medium density non woven material. Among Buff and Blend products, the Mini Brush is the least aggressive, making it ideal for producing fine finishes on irregular shaped parts.

Benefits of Open Web Abrasives

The Standard Abrasives™ MD Mini Brush is constructed with aluminum oxide mineral and nonwoven nylon fibers bonded with resin, resulting in a dense open web. Resin bonds tolerate heat and help enhance overall durability of the abrasive. Aluminum oxide mineral cuts sharp and is friable, fragmenting under heat and pressure to reveal sharp cutting edges, offering a consistent cut throughout the life of the abrasive.

Gaps between the nonwoven nylon fibers allow swarf and debris to escape, so the abrasive does not get clogged with buildup and keeps cutting sharper for longer. Moreover, the nylon fibers are buoyant and responsive, so you get a consistent cut without gouging or marring the workpiece. Given that maintaining part geometry – especially on fabricated steel parts – is often a top concern, the mini brush’s ability to conform to the substrate without compromising part geometry is one of its key benefits. It helps reduce the likelihood of having to discard scrap parts due to incorrect tolerances, as well as minimizes the need for rework.

Broad Range of Grades

The Mini Brush is color coded by grade to help users quickly identify the right grade for their application. Available grades range from very fine to extra coarse to meet the needs of many different surfaces. Medium and fine grades will cut less aggressively but leave a finer scratch pattern, whereas coarse grades will cut more aggressively and leave a rougher scratch pattern.

Altogether, the Mini Brushes provide a quality, fast and easy solution for restoring original steel finishes.

Quality Standard Abrasives™ Solutions for Industrial Applications

The Standard Abrasives brand has supplied quality abrasives to the metalworking industry for over 50 years. Customers rely on our broad offering of high performance products including coated, bonded, and non woven abrasive lines.

- Delivers high-quality finishes with sharp cutting and self-renewing aluminum oxide mineral

- Open web is load resistant, prolonging abrasive service life

- Non-woven material is spongy and responsive, conforming to most surface geometries

- Resin bond is heat resistant and withstands repeated wear

- High Strength Buff and Blend material has great tear resistance

- Easy to use

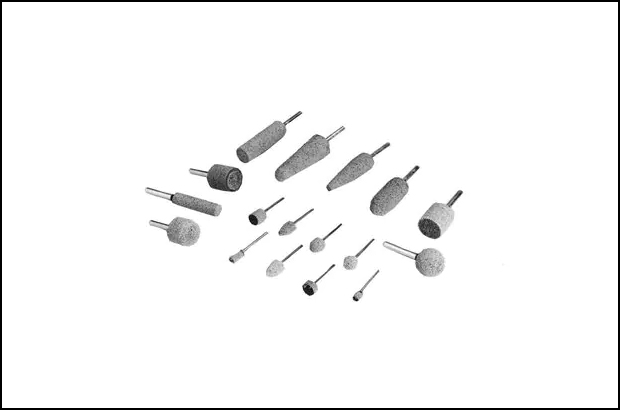

Scotch-Brite™ EXL Unitized Mounted Point

Our Scotch-Brite™ EXL Unitized Mounted Point lightly deburrs, blends and finishes metal and plastic parts. The versatile assortment of shapes and sizes make the EXL Unitized Mounted Point a good match for small parts with hard-to-reach areas.

Our Scotch Brite™ EXL Unitized Mounted Point comes in a variety of ANSI (American National Standards Institute) shapes and sizes, ideal for light blending and deburring of smaller workpieces. The abrasive point is securely fastened to a metal spindle, so it can be used with a die grinder. The variety of abrasive sizes helps operators effectively finish various parts.

The EXL Unitized Mounted Point reduces the risk for smearing or blemishing the surface. It also features nonwoven web that is load resistant and keeps the abrasive minerals cutting at high performance by limiting clogging of the nylon fibers.

Unitized products are produced by compressing and curing multiple layers of abrasive material together. The tough, layered, unitized construction gives the abrasive higher density and more durability, making our Scotch Brite™ EXL Unitized Mounted Point an exceptional choice for small workpieces that require a consistent finish.

- Mounted point is securely fastened to a metal spindle for safe use with die grinder

- Abrasive lightly deburrs and finishes the workpiece without changing geometry

- Resists smearing for cleaner surfaces and less preparation

- Nonwoven construction resists loading during product use

- Unitized production method compresses abrasive web for greater density and durability